- Home Page

- Company Profile

-

Our Products

- Analog Lab Training Modules

- IGBT Characteristics Apparatus

- LR Circuit With A Source Of Alternating E.M.F

- LCR Resonance Circuit with Built in Oscillator

- Conversion of Galvanometer to Ammeter

- BH Curve Apparatus with Solenoid

- Conversion of Galvanometer to Voltmeter

- Hall Effect Experiment Apparatus

- Transistor Characteristics Apparatus (AE212)

- Charging and Discharging of Condenser

- Photo Cell Characteristics Apparatus

- Biasing Techniques of Transistor (BJT)

- Tunnel Diode Characteristics Apparatus

- Study of Switching action of a Transistor (BJT)

- Boltzman Constant Kit

- Transformer characteristics Apparatus

- Solar Cell Characteristics Apparatus

- LCR Resonance Apparatus

- Plancks Constant Apparatus (AE206)

- Flashing Quenching of Neon Apparatus

- RC Circuit as High Pass and Low Pass Filters

- Conversion of Galvanometer to Voltmeter and Ammeter

- PN Junction or Semiconductor Diode Characteristic

- Clipping and Clamping Circuit Apparatus

- Work Function of Diode (Richardson Law (AE 209)

- Voltage Doubler and Tripler Circuit

- Half Wave Full Wave and Bridge Rectifier Apparatus

- Transistor Characteristics Apparatus

- Planck Constant Determination Using LED

- UJT Characteristics Apparatus and UJT as Relaxation Oscillator (Combined Model)

- Plancks Constant Experiment

- Quinck`s Tube Method

- Resistances in Series Parallel Apparatus

- LCR Impedance Circuit Apparatus

- Energy Band Gap of PN Junction Diode (AE218)

- Pentode Valve Characteristics Apparatus

- Thermistor Characteristics Apparatus

- FET Characteristics Apparatus

- Zener Diode Characteristics and Voltage Stabilization

- Diac Characteristics Apparatus

- LDR Characteristics Apparatus

- Ionization Potential of Mercury

- PN Junction or Zener Diode or LED Characteristics Apparatus

- Photo Transistor Characteristics Apparatus

- Peak Average Rms Value of a AC Signal

- Diode Valve Characteristics Apparatus

- Work Function of Diode (Richardson Law (AE 209)

- Triode Valve Characteristics Apparatus

- Resistivity Of Semiconductors by four probe method

- KCL and KVL ( Kirchoff's law)

- Three Terminal voltage Regulator Trainer

- Voltage Regulation using Zener Diode & Transistor

- Study of Voltage Regulation using IC LM 317

- Characteristics of Optoelectronic Devices

- Photo Diode Characteristics Apparatus

- LED Characteristics Apparatus

- Triac Characteristics Apparatus

- MOSFET Characteristics Apparatus

- UJT Characteristics Apparatus

- SCR Characteristics Apparatus

- Ripple Factor Apparatus

- BH Curve Apparatus

- Voltage Stabilization Characteristics of Zener Diode

- Zener Diode Characteristics Apparatus

- PN Junction Diode / Semiconductor Diode Apparatus

- Electronic Component and Valves Mounted On Board

- Voltage Regulation by 78 series voltage regulators

- Rc Transmission Line

- Semiconductor Characteristics Trainer

- Laboratory Power Supplies

- Sodium Vapor Lamp Transformer

- Daniel Cell Substitute Electronic

- Electrophoresis Power Supplies

- Lechlanche Cell Substitute Electronic

- Dual Channel Variable DC Regulated Power Supplies

- Millikans Oil Drop Apparatus Power Supply

- Standard Cell (Electronic)

- IC Regulated Battery Eliminators

- DC Regulated Power Supplies

- DC Power Supplies

- Amplifiers Characteristics

- TRANSISTOR AMPLIFIER TRAINER WITH INBUILT SINE WAVE GENERATOR AND AC MILLI VOLTMETER (CE,CB,CC)

- Study of Class A B AB and Push Pull Amplifier

- Transistor Push Pull Amplifier / Transformer Coupled Amplifier

- Transistor Amplifier Circuits (CE CB CC)

- FET Common Source Amplifier

- RC Coupled Amplifier with Function Generator and AC Digital meters

- Two Stage RC Coupled Transistor amplifier

- Common Emitter Transistor Amplifier

- Common Base Transistor Amplifier

- Common Collector Transistor Amplifier

- Complementary Symmetry Amplifier

- Common Base Amplifier with Function Generator and AC Digital meters

- TRANSFORMER COUPLED (PUSH PULL) AMPLIFIER TRAINER WITH SINE WAVE GENERATOR & Digital Meters

- E-M Experiments

- Oscillators Experiments

- Multivibrators Trainers

- Bread Boards Trainers

- Digital Lab Training Modules

- Analog to Digital Converter kit

- Demorgan Theorem kit

- RS D T JK and JK MASTER SLAVE FLIP FLOP TRAINER

- Study of Left , Right & Programmable Shift Register

- Adder and Subtractor using NAND Gates

- Multiplexer and Demultiplexer 16 bit

- Logic Gates using Universal gates

- Verification of Boolean Identity and Demorgans Theorem

- RAM Circuit using IC 7489

- Study Of 4 Bit Adder And Subtractor

- Basic Logic Gates using Discrete Component (5 in 1)

- Digital to Analog Converter Kit

- Digital Trainer to verify Half Adder and Full Adder

- Study of Arithmatic Logic Unit (ALU)

- Study of Encoder and Decoder Circuits

- Flip Flops using TTL ICs and NAND Gates

- Study of Parity Generator/Checker

- Study Of Logic Gates Using Ttl ICs 6 in 1

- Study of 4 Bit Counters(Synchronous Asynchronous)

- Study of Logic Gates using TTL ICs (7 in 1)

- TTL IC Characteristics Apparatus

- CMOS IC Characteristics Apparatus

- Filter Circuits

- Communication Lab Training Modules

- Delta Modulation and Demodulaion

- Pulse Position Modulation and Demodulation

- Phase Shift Keying (PSK) Modulation & Demodulation

- Amplitude Modulation and Demodulation using Transistors

- FSK Modulation and Demodulation

- Study of Pulse Width Modulation and Demodulation

- Pulse Amplitude Modulation and Demodulation Trainer

- Digital Communication Trainer

- Antenna Trainer

- Transmission Line Trainer

- Mobile Phone Trainer

- Analog Communication Trainer

- HAMMING CODE (ERROR DETECTION CORRECTION) TRAINER

- FOURIER SYNTHESIS SYSTEM TRAINER

- Data Reformatting & Carrier Demod Receiver Trainer

- Data Formatting and carrier Modulation Transmitter Trainer

- Tdm Pulse Code Demodulation Receiver Trainer

- TDM Pulse Code Modulation Transmitter Trainer

- Delta , Adaptive Delta & Delta Sigma Modulation & Demodulation Trainer

- TDM Pulse Amplitude Modulation Transmitter Trainer

- Dsb Ssb Amplitude Modulation (Am) Transmitter Trainer

- Fibre Optic Communication Trainer

- Frequency Division Multiplexing Modulation

- Pam-pwm-ppm Modulation Demodulation Trainer Kit

- Eprom Trainer

- Analog Signal Sampling and Reconstruction Kit

- Pulse Code Modulation and Demodulation

- Pre-emphasis De-emphasis Trainer

- Phase Modulation & Demodulaion

- Amplitude Shift Keying Modulation & Demodulation

- DSB/SSB AMPLITUDE MODULATION (AM) RECEIVER TRAINER

- Amplitude Modulation and Demodulation

- Frequency Modulation and Demodulation

- Fibre Optic Trainer Analog

- Power Electronic Trainer

- Physics Lab Experimental Setups

- Temperature Coefficient of Resistance for Platinum Using a Platinum Resistance Thermometer Callender and Griffiths Bridge

- SPEED OF SOUND USING KUNDTS TUBE EXPERIMENT

- Resolving Power of a Diffraction Grating Using Spectrometer & Mercury Lamp.

- Study of Dielectric Constant and Curie Temperature of Ferroelectric Ceramics

- Magnetic Susceptibility By Gouys Balance Experiment

- Stefan Constant Black Body Radiation Apparatus

- Choke Characteristics Apparatus

- PHOTOCONDUCTIVITY EXPERIMENT

- Newtons Ring Experiment Setup

- TO DETERMINE THE REFRACTIVE INDEX OF LIQUID BY TOTAL INTERNAL REFLECTION USING WOLLASTON AIR FILM

- Measurement Of Magnetoresistance for Semiconductors

- Michelson Interferometer

- Calibration of Voltmeter and Ammeter using Potentiometer

- Determination of Youngs Modulus using Cornus Method.

- ASICO Absorption Spectrum of Iodine Vapour

- ASICO COUPLING COEFFICIENT OF PIEZOELECTRIC CRYSTAL

- Laser Experimental Set Up (Diode Laser)

- To Study the Biot Savarts Law

- Spectrometer Experiment

- High Resistance Using Substitution Method

- Laser Experimental Set Up (He-Ne Laser)

- Polarisation of Light by Quater Wave Plate Experiment

- Ultrasonic Interferometer

- Babinet Compensator

- Wavelength of Diode Laser using Diffraction Grating

- Lissajous Figure Apparatus

- Determine the Polarization of Light by Reflection and Determine the Polarizing angle for Air Glass Interface

- To Determine the Fermi Energy of Copper

- Stefan Constant Apparatus

- FABRY PEROT INTERFEROMETER

- THERMOSTAT CHARACTERISTICS TRAINER

- Half Shade Polarimeter Setup

- g by Free Fall Apparatus Experiment

- Constant Deviation Spectrometer CDS

- e by k using Silicon Transistor

- Surface Plasmon Resonance (SPR) setup

- Sextant - SXT

- Lamp And Scale Arrangement

- Thermo emf for Copper Iron Thermocouple

- Different types of Gratings and Slits for Laser Experiments

- Laser Grating 3 in 1

- Coulomb Meter

- High Resistance By Leakage Method Experiment

- Velocity of Ultrasonic waves in Kerosene Liquid

- Helium Neon Laser 2mW

- Diode Laser 5mW

- Dielectric Constant for Solids and Liquids

- Dielectric Constant Apparatus (Solids)

- Rydberg Constant Measurement Complete Set-up

- Franck-Hertz Argon Tube Experiment Set

- Calibration of Wattmeter Using Dc Potentiometer

- Malus Law Apparatus

- Spectrum Tube Power Supply

- Fabry-Perot Etalon

- Spot Reflecting Galvanometer

- Ballistic Galvanometer

- Determination of Plancks constant from the LED

- Magnetic Field In Helmholtz Coil Experiment Setup

- Plancks Constant using Black Body Radiation

- Thermo Emf of Thermocouple Using Ten Wire Potentiometer

- Mutual Inductance Of Two Coils Using Absolute Method

- ASICO COMPARE THE EMF OF TWO PRIMARY CELLS USING DC POTENTIOMETER

- Lattice Dynamic kit

- Thermal Conductivity of Copper by Angstrom Method

- PE HYSTERISIS LOOP TRACER

- To Determine the Attenuation and Numerical Aperture of Fiber Optic Cable

- Study the Faraday Effect and Measure the Verdant Constant of Glass Rod

- Differential Amplifier Using Transistors

- Electron Spin Resonance Spectrometer ESR

- Measurement of field Strength B and its variation in circular Helmholtz Coil, Determine the DB/DX

- Dispersion Power of a Prism Using Spectrometer & Mercury Lamp

- Laser Diffraction Using Single & Double Slit

- Magnetostriction with Michelson Interferometer

- Millikan Oil Drop Apparatus

- Michelson Interferometer Optical Bread Board Model

- Testing Measuring Instruments

- DSO 20MHz Colour LCD Display

- Digital DC Ammeter LED Type Mains operated

- Digital DC Voltmeter LED Type Mains operated

- PLC Trainer

- Vaccum Tube Volt Ohm Meter (VTVM)

- Gauss Probe

- Digital Flux Meter / Gauss Meter

- Digital AC Millivoltmeter

- Universal IC Tester

- Digital IC Tester

- Analog / linear IC Tester

- Diode Lasers (Green Colour) with Power Supply

- CRO 30MHz, Dual Channel, 2 Trace

- CRO 20MHz, Dual Channel, 2 Trace

- CRO 10MHz, Single Trace

- Signal Tracer

- EPROM Eraser

- LCD Display Stroboscope

- Distortion Factor Meter

- LCR Q Meter

- Sweep Generator With X-Y Display With Marker

- DSO 60 MHz

- DSO 100 MHz

- Power Meter

- Ohms Meter Series and Shunt Type

- Digital AC Milli Voltmeter

- Function Generators

- Function Generator 0.1Hz To 1MHz

- Function Generator 0.1Hz to 1MHz Frequency counter

- RF Oscillator 3MHz-8MHz

- Pulse Generator 0.1Hz-1MHz

- 8 digit frequency counter 10 Hz~2.4GHz

- RF Oscillator 3-8 MHZ

- AF RF Signal Generator 100kHz-30MHz

- Spot Frequency Oscillator 400 1K 3K Hz

- Function Generator 2Hz to 20MHz

- Function Generator 1Hz to 10MHz

- Function Generator 0.3Hz to 3MHz

- Function Generator 0.2Hz to 2MHz

- Audio Frequency Function Generator 1Hz to 200KHz

- Audio Frequency Function Generator 1Hz to 100KHz

- Fixed Frequency Sine Wave Oscillator 1KHZ

- Digit Digital Multimeter (Manual Range)

- AM / FM Signal Generator

- Function Generator 200 KHZ Digital

- Decade Boxes

- Microprocessor Lab

- AC Bridges

- Campbell Bridge Trainer ( Mutual Inductance Bridge)

- Hay Bridge with Oscillator and Null Detector

- Religh Bridge

- Schering Bridge with Null Detector and Oscillator

- Owen Bridge

- Kohlrausch Conductivity Bridge

- Anderson Bridge with Oscillator and Null Detector

- DC Source 0-10VDC/5 AMP

- LCR / AC Bridge

- Callender & Griffith's Bridge

- Carey Foster Bridge Setup

- Desauty Bridge with Null Detector and oscillator

- Wheatstone Bridge (Portable)

- Weins Bridge (Frequency Measurement)

- Industrial Kelvin Double Bridge

- Maxwell Inductance Bridge

- Weins Bridge (Capacity Measurement)

- Kelvin Bridge Setup

- Null Detector Digital

- KELVIN'S DOUBLE BRIDGE TRAINER (DIGITAL)

- Microwave Lab Experiments

- Network Theorems

- Verification Of Maximum Power Transfer Theorem

- Verification of Network Theorem

- Verification Of Thevenin's Theorem

- Verification Of Norton's and Thevenin's Theorem

- Verification of Norton's Theorem

- Verification of Milliman`s Theorem

- Verification of Superposition Theorem

- Verification of Reciprocity Theorem

- Verification of Tellegan's Theorem

- Instrumentation Lab

- Measurement of Temperature using Thermocouple

- Torque Measurement Trainer

- Measurement of Temperature using RTD

- Sensor Trainer Kit

- Strain Guage Trainer With Cantilever

- Photo Electric Pickup Trainer

- Photo Sensor Trainer

- Humidity Sensor Trainer

- Piezo Electric Transducer Trainer

- Capacitive Pickup Trainer

- Angular / Linear Displacement Trainer

- LDR / Opto Isolator Trainer

- Pressure Measurement Trainer

- Load Cell Trainer

- LVDT Transducer trainer

- Inductive Pickup Trainer

- Ultrasonic Distance Measurement Trainer

- Magnetic Pickup Trainer

- TEMPERATURE TRANSDUCER TRAINER

- PCB Designing Lab

- Proto Developers Stripper

- Dye/Developer 2 In 1 Unit

- UV Exposure Machine

- PCB Etching Machine

- Film Making Unit

- Roller Tinning Machine

- PCB Drilling Machine

- PCB Curing Machine

- Photoresist Dip Coating Machine

- PCB Shearing Machine

- Art Work Table

- Dry Film Laminator

- Ammonical Etching Machine

- Vertical Reprographics Camera

- Electronic Components Display Boards

- Dynamic Demonstrators Trainers

- Control System Lab

- PID Controller

- Compensation Design System

- Relay Control System Trainer

- Study Of Second Order Network

- DC Motor Position Control System Trainer

- AC Motor Position Control System Trainer

- Digital Control System Trainer

- DC Speed Control System Trainer

- Advanced PID Controller Trainer

- Temperature System Simulator

- Linear System Simulator

- Magnetic Amplifier Trainer Series & Parallel

- Magnetic Amplifier Trainer Positive & Negative

- Potentiometric Error Detector Trainer

- Synchro Transmitter Receiver Trainer

- Stepper Motor Controller with Microcontroller

- Speed Torque Characteristics of DC Servomotor

- Light Intensity Control System

- Speed Torque Characteristics of AC Servomotor

- Analog Lab Training Module

- Transformers

- Educational Desk Stand Meters

- Networking Lab

- Portable Meters

- Embedded lab

- Operational Amplifier trainers

- Operational Amplifier as Inverting & Non Inverting

- Operational Amplifier Trainer (with DPM)

- Operational Amplifier as Schmitt Trigger

- Operational Amplifier as Voltage & Current Feedback Amplifier

- Operational Amplifier as Voltage to current & current to Voltage Convertor

- Operational Amplifier as Voltage Comparator

- Study of Logrithmic Amplifier (AE 313 )

- Op amp as Linear Wave Shaping Circuits

- Applications Of Operational Amplifier

- Operational Amplifier as Differentiator & Integrator

- Study of Op Amp as Instrumentation Amplifier

- Study of Characteristics of Operational Amplifier

- Analog Lab Training Modules

- Contact Us

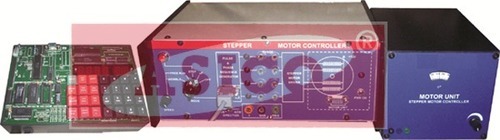

Stepper Motor Controller with Microcontroller

Product Details:

- Usage Stepper motor speed and position control in automation and robotics

- Power 12V DC, 2A minimum (motor dependent)

- Display 7-Segment LED/LCD display for step and status indication

- Voltage Input voltage range: 12V to 24V DC

- Product Type Stepper Motor Controller with Microcontroller

- Material High-quality PCB, ABS/plastic enclosure

- Design Compact, modular, PCB-based controller with connectivity terminals

- Click to view more

X

Stepper Motor Controller with Microcontroller Price And Quantity

- 1 Unit

- LED status indicators for power and motor state

- Full step, half step, microstepping (if firmware supports)

- Manual through buttons or switches, or external signal/serial communication

- Compatible with 2-phase and 4-phase stepper motors

- Standard motor drive outputs (A+, A-, B+, B-)

- Up to 2.5A per phase (motor dependent)

- 0°C to 55°C

- Onboard microcontroller (e.g., Atmega328/STM32)

- Ventilated plastic

- Panel mount and desktop use

- Overcurrent, thermal shutdown, polarity protection

- UART/RS232/TTL (depending on version)

Stepper Motor Controller with Microcontroller Product Specifications

- N/A (mains powered, not battery operated)

- Stepper Motor Controller with Microcontroller

- External DC Adapter / SMPS

- Input voltage range: 12V to 24V DC

- High precision, typically 1.8 per step

- Compact, modular, PCB-based controller with connectivity terminals

- Approx. 350 grams

- High-quality PCB, ABS/plastic enclosure

- N/A (no lighting/illuminant feature)

- N/A (not applicable to motor controller)

- 12V DC, 2A minimum (motor dependent)

- Stepper motor speed and position control in automation and robotics

- Approx. 165mm x 110mm x 35mm

- 7-Segment LED/LCD display for step and status indication

- LED status indicators for power and motor state

- Full step, half step, microstepping (if firmware supports)

- Manual through buttons or switches, or external signal/serial communication

- Compatible with 2-phase and 4-phase stepper motors

- Standard motor drive outputs (A+, A-, B+, B-)

- Up to 2.5A per phase (motor dependent)

- 0°C to 55°C

- Onboard microcontroller (e.g., Atmega328/STM32)

- Ventilated plastic

- Panel mount and desktop use

- Overcurrent, thermal shutdown, polarity protection

- UART/RS232/TTL (depending on version)

Stepper Motor Controller with Microcontroller Trade Information

- 5 Unit Per Week

- 4-5 Days

Product Description

DESCRIPTION

This experimental set up is designed to study of a small stepper motor fitted with calibrated dial and servo potentiometer in see through cabinet. The main unit has a motor controller, pulse sequence generator, variable frequency square wave oscillator, single step mono pulsar and wobbling signal to observe dynamic response. The unit can be interface with µPkit.

TECHNICAL SPECIFICATIONS

- TTL circuit for single stepping & free running mode frequency 10-100Hz.

- Wobble mode.

- Direction selector.

- LED indicators for phase sequence.

- µPinterface.

- Calibrated dial for position monitoring.

- Position pick up by servo potentiometer.

- IC regulated power supply for complete circuitry.

- 220V

- ±10%, 50Hz mains operated.

- User's Manual with patch cords.

- Power : 12V/1A

- Torque : 2.0/3.0 kg/cm

- Step Angle : 1.8 degree

Advanced Motor Control Capabilities

Control multiple types of stepper motors, ranging from 2-phase to 4-phase, with selectable step resolutions including full, half, andif supportedmicrostepping. Achieve accurate speed and position management, with precision typically around 1.8 per step, making it ideal for a range of automation purposes.

Flexible Communication and Operation

Operate the controller manually using built-in buttons or externally via serial interfaces such as UART, RS232, or TTL, depending on the version. This versatility makes integration simple in both standalone and automated scenarios, offering users control based on their requirements.

Reliable Design with Safety Features

Benefit from advanced protection mechanisms including overcurrent, polarity protection, and thermal shutdown. The ventilated ABS enclosure ensures the device stays cool and protected, while LED indicators offer clear visual feedback for power and motor state, enhancing user safety and device longevity.

FAQs of Stepper Motor Controller with Microcontroller:

Q: How do I connect and control stepper motors with this controller?

A: You can connect 2-phase or 4-phase stepper motors using the standard terminal outputs (A+, A-, B+, B-). Control is achieved either manually through onboard buttons or switches, or remotely via external signals using UART/RS232/TTL communication interfaces, depending on the model.Q: What types of stepper motors does the controller support?

A: This controller is compatible with both 2-phase and 4-phase stepper motors, supporting various drive configurations for wider application versatility in different industrial and robotics systems.Q: When is microstepping available, and what are its benefits?

A: Microstepping is supported if the installed firmware version enables it. Microstepping provides smoother motor operation and higher positioning resolution, reducing vibration and improving accuracy beyond standard full or half steps.Q: Where can this stepper motor controller be installed?

A: With its compact, modular design and options for both panel mounting and desktop use, this controller can be installed in control panels, machinery enclosures, or as a standalone desktop device in laboratories or workshops.Q: What safety and protection features are included?

A: The controller is equipped with overcurrent protection, thermal shutdown to prevent overheating, and polarity protection to safeguard against incorrect power connections, ensuring reliability during operation.Q: What benefits does the 7-segment LED/LCD display provide?

A: The integrated display clearly shows steps and status, allowing real-time monitoring of motor position, steps, and operational states. This helps with rapid diagnostics and facilitates precise manual operation.Q: What is the required power supply and maximum output current?

A: The controller operates on a 12V to 24V DC input (minimum 2A depending on motor), and can deliver up to 2.5A per phase, ensuring sufficient power for most stepper motors in industrial and automation tasks.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese